You know how we sometimes joke about how someone’s “left the transmission back there” if they’re changing gears really rough? Or we joke about a car being in such poor repair that (unspecified) bits will fall off?

I NEVER KNEW THAT COULD REALLY HAPPEN.

Until it did, yesterday. It wasn’t the transmission, but it was a hunk of metal from the engine, steaming mightily.

We’d just alighted (gotten off), and the bus had set off again, but the part stayed right next to us, and the bus stopped rather suddenly, about 100 feet down the hill. People poured out, and looked around, and we pointed out the part in the road, and so they came up to look at it – the driver, for his part was already on his phone, presumably to the bus company. We looked around for a stick to move this steaming hunk of metal out of the road, but there were none; Chris kicked it up onto the grass, since it’s just after a bend in the road, and we certainly didn’t want anyone to run over it.

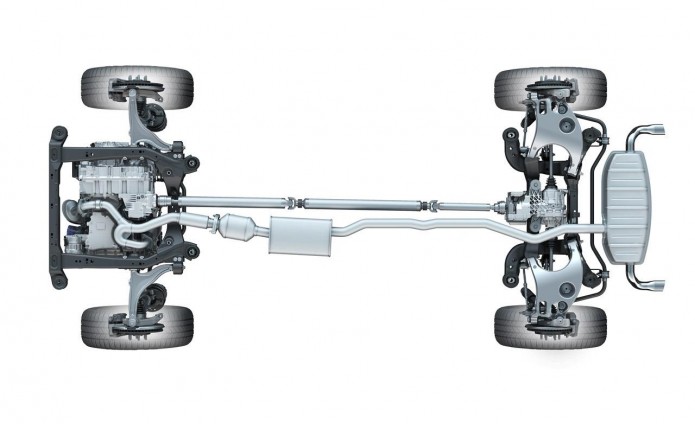

The part is part of the drive train. As I understand it, the business part of a four-wheel-drive vehicle looks basically like this:

Figure 1; Source

The left is the front; the right is the rear. The engine (on the left) does a lot of stuff to create motion to pass to the wheels to make them go round. This motion, on a 4-wheel-drive vehicle, is passed to the rear wheels along the straight rod that runs back to them. (Ignore the funny bent one; that’s the exhaust.) That straight rod is the drive train, and if you look closely, you’ll see it’s not one rod, but actually 3. The two joins between the 3 rods aren’t secured completely, so that they can slide about a very little bit when the vehicle hits bumps and the like.

Figure 2; Source

The middle section of that drive train (the straight bit in the middle) is actually three parts instead of the one it looks like. There’s a central rod, and then either end has a hunk of metal that is a U-shape at one end, and a cup at the other end that fits over the rod. It just sticks over the rod, like a push-on lid for a tupperware container, though I’m told there should be teeth inside to help it stay (what with it not being able to harness the plastic magic that tupperware does). The U-shape at the other end is attached to the next portion of the drive train via pegs: on Figure 2, you remove the somewhat decorative-looking disc towards the left, and then a hole presents itself. You put a long peg with a bit of screw threading at the bottom into there, screw it into the disc in the middle of the two U-shapes, and the rest is just bare metal peg, with bearings on either side, to let the peg swivel around as needed. Do this at all four points around that disc (both ends of the two Us), and then do it again on the other side of the drive train rod. So you get some give that way, and you get some give because the other end isn’t affixed firmly, either.

So what happened with the bus yesterday? Near as we can figure: Looking again at the steaming hunk of metal, we see that the two bits that were fixed via the pegs were sheared off – too much stress – and when turned just enough, the cap end just fell off the rod and ended up in the road. Why? We suspect a combination of (1) that driver driving that bus like a maniac along these winding High Peak roads – we had him both ways, and I was grasping the bar in front of me almost the whole time* to keep from being flung more than necessary – and therefore stressing that part, and (2) High Peak bus company’s lackadaisical approach about maintaining its fleet – breakdowns are pretty common on that line.

(*On the way home, we got behind another bus for a piece of road, the Stagecoach 358, and then I got to sit back and enjoy the ride, not being flung about endlessly. Really wish that driver we had would calm down and learn that there are more speeds available than “slam on brake” and “slam on gas.”)

While still a mile from the end of the line, we were thankfully close enough that all the passengers were able to easily get where they were going. There was one woman all in a tizzy because she needed to catch the last bus to Huddersfield at 5:10pm, and it was 4:50pm; it would be dear to get to after that (£15.50 by train or perhaps £40 by taxi). Thankfully, one of the other ladies summoned help in the form of a relative to come drive that lady to the bus stop, so she was taken care of. Not that this stopped her from laying into the bus driver with her problem once he hung up the phone, mind you – as if he was somehow supposed to magically make the bus instantly work again. It perhaps would have struck me as fair if she didn’t already have a lift on the way, and if she’d phrased it better.

We were so lucky that, of all the places for the bus to break down, it did so in a relatively convenient place, and not out in the middle of nowhere – not on Long Hill, not on the hill between Glossop and Hayfield, no. We’d have all been stranded. It took an hour and a half for a tow truck to arrive for the bus. I just really hope they didn’t leave all the people stranded who were expecting the bus going back again the other way – it had one more run to make before the end of its day.

Chris explained all these nitty gritty details to me, and showed me various diagrams, and so I understand it enough, but I’m still absolutely shocked that a part of the bus literally FELL OFF IN THE ROAD. Thank heavens it didn’t hit us!